Depth: supply chain logistics "neck", how to restart the trillion level automobile industry?

The following article is from G7 IOT (ID: g7_smart)

I believe that few people will pay special attention to automobile supply chain logistics before March and April. After all, even the automobile industry in the trillion market accounts for only 7% of China's freight market. However, this 7% proportion has become the fuse for the supply interruption of the whole automobile industry in the environment of the outbreak of the epidemic in Jilin and Shanghai not long ago.

In April, he Xiaopeng said on his microblog: "if Shanghai and surrounding supply chain enterprises cannot find a dynamic way to resume production, all vehicle factories in China may stop production in May." In a word, we can see the huge butterfly effect of Shanghai as the core of the national automobile industry community under the epidemic. In addition, once the automobile supply chain logistics is fused, it will be even worse for the automobile industry with prominent cluster effect and long production chain.

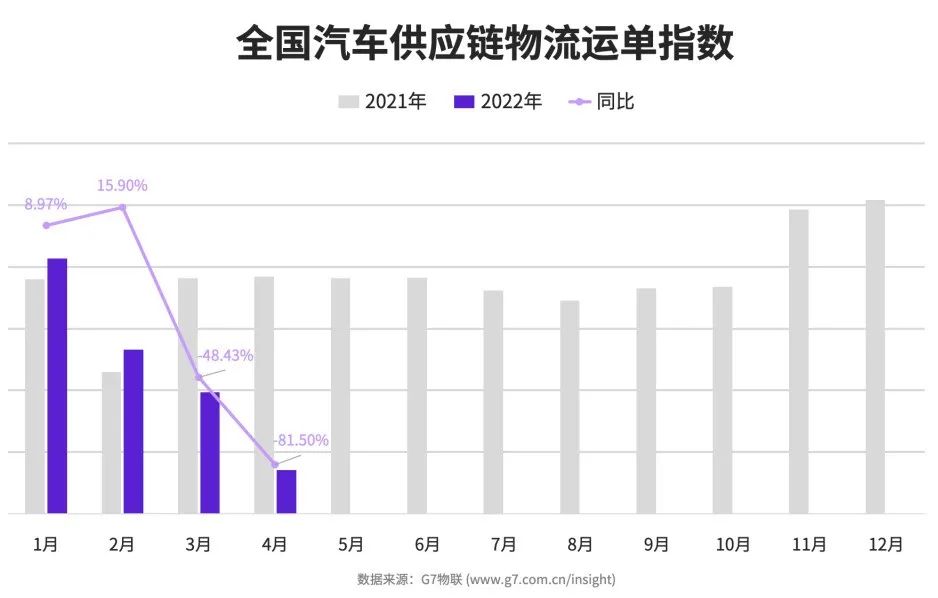

According to the statistics of G7 IOT data platform, since March 2022, the national automobile supply chain logistics waybill index has ended its growth for two consecutive months, with a year-on-year decrease of 48.43%, almost halving, while the index fell sharply by 81.5% in April.

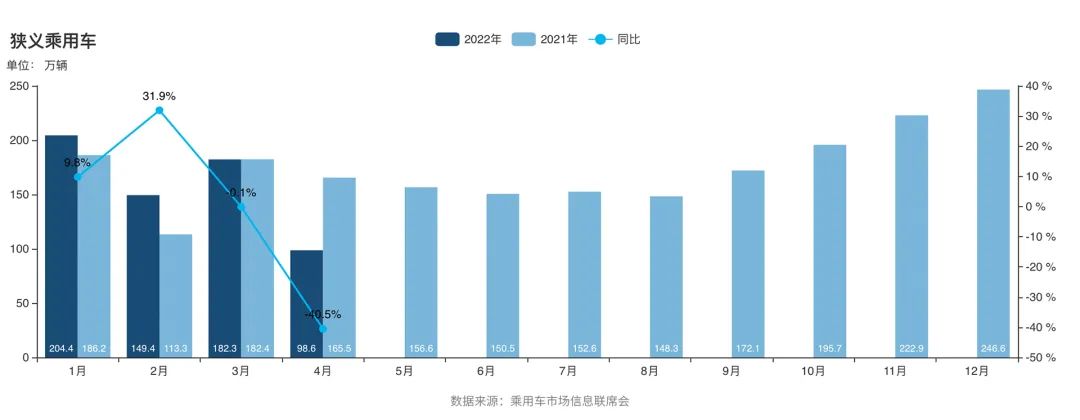

The impact of the epidemic on the automotive industry began to appear one by one through data. According to the statistics of the passenger car Federation, the retail sales of the passenger car market in April 2022 was 1042000, with a year-on-year decrease of 35.5% and a month on month decrease of 34.0%. The year-on-year and month on month growth rate of retail sales in April were at the lowest in the history of the month. In terms of production, 986000 narrow passenger cars were produced in April, down 40.5% year-on-year and 45.9% month on month.

Affected by the epidemic, the rupture of automobile supply chain logistics makes local parts suppliers unable to supply in time, and many manufacturers also stop production. In addition, the uncontrollable efficiency of logistics transportation and some dealers in China choose to close their stores, both the production end, circulation end and sales end are under great pressure.

Affected by the epidemic, the rupture of automobile supply chain logistics makes local parts suppliers unable to supply in time, and many manufacturers also stop production. In addition, the uncontrollable efficiency of logistics transportation and some dealers in China choose to close their stores, both the production end, circulation end and sales end are under great pressure.

01

The stagnant transport capacity hurts the automobile industry cluster

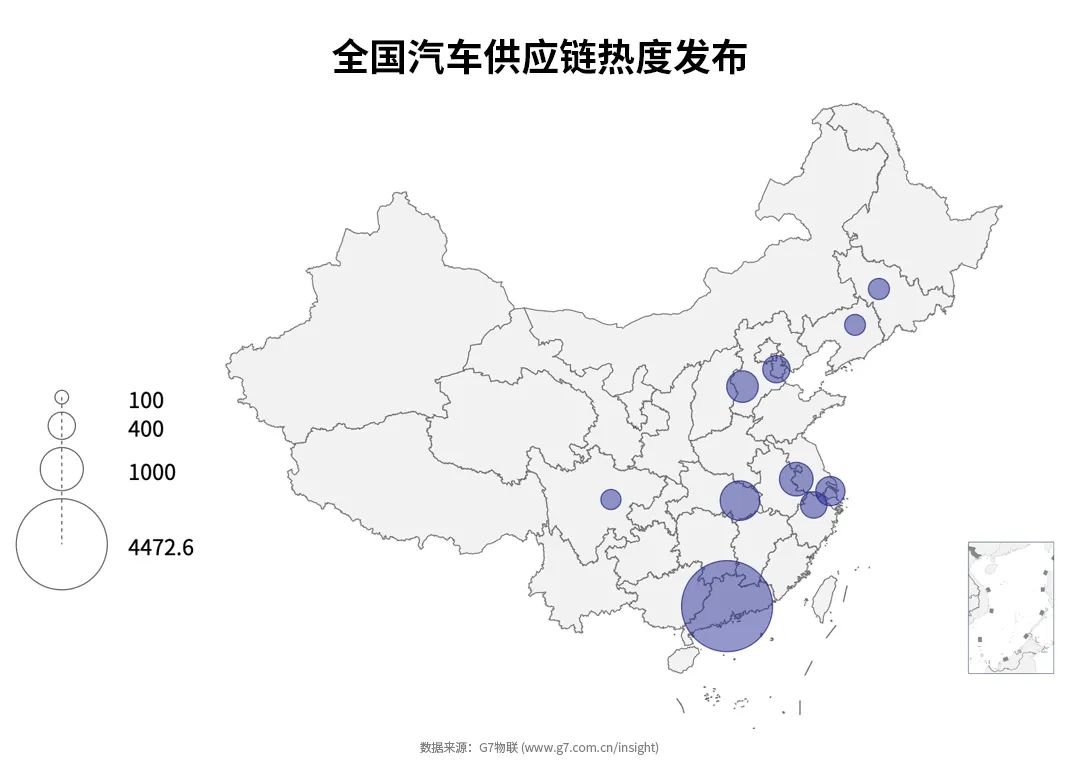

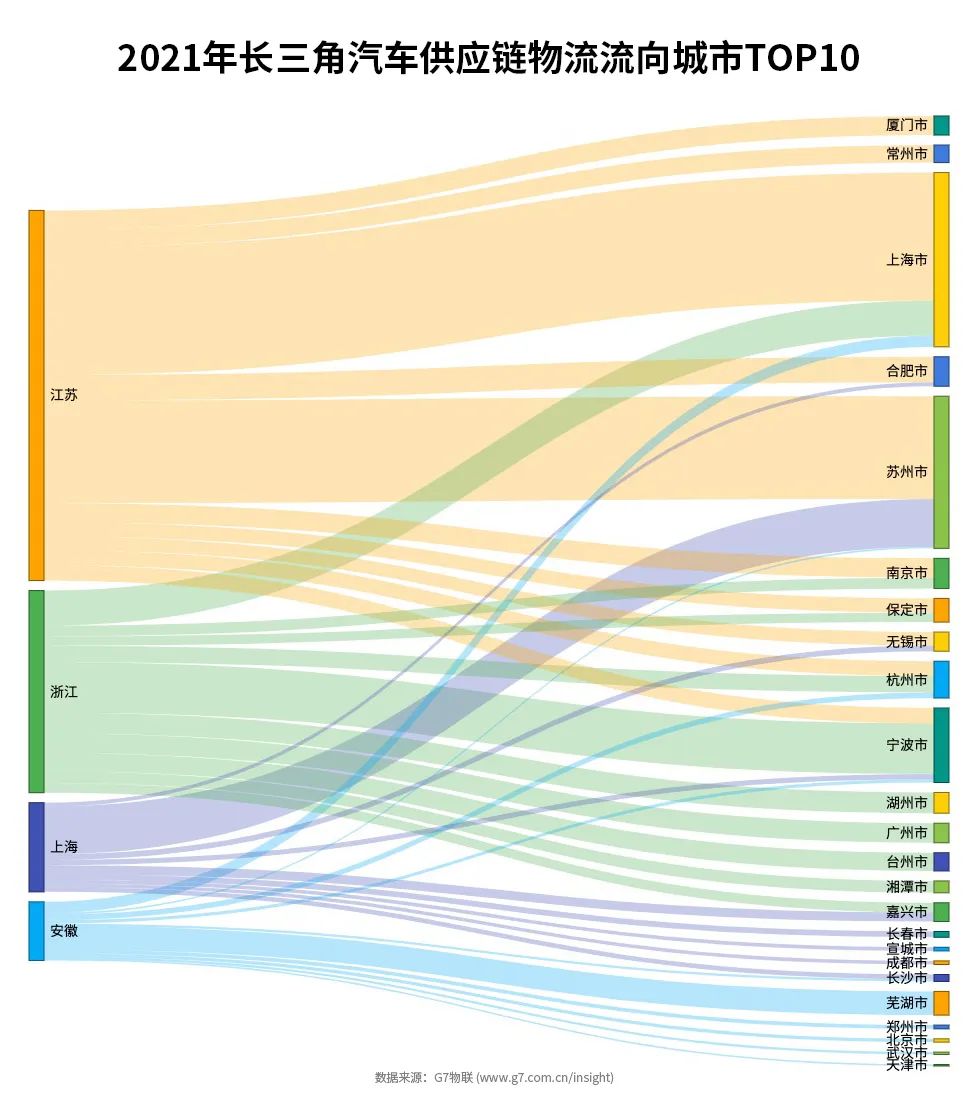

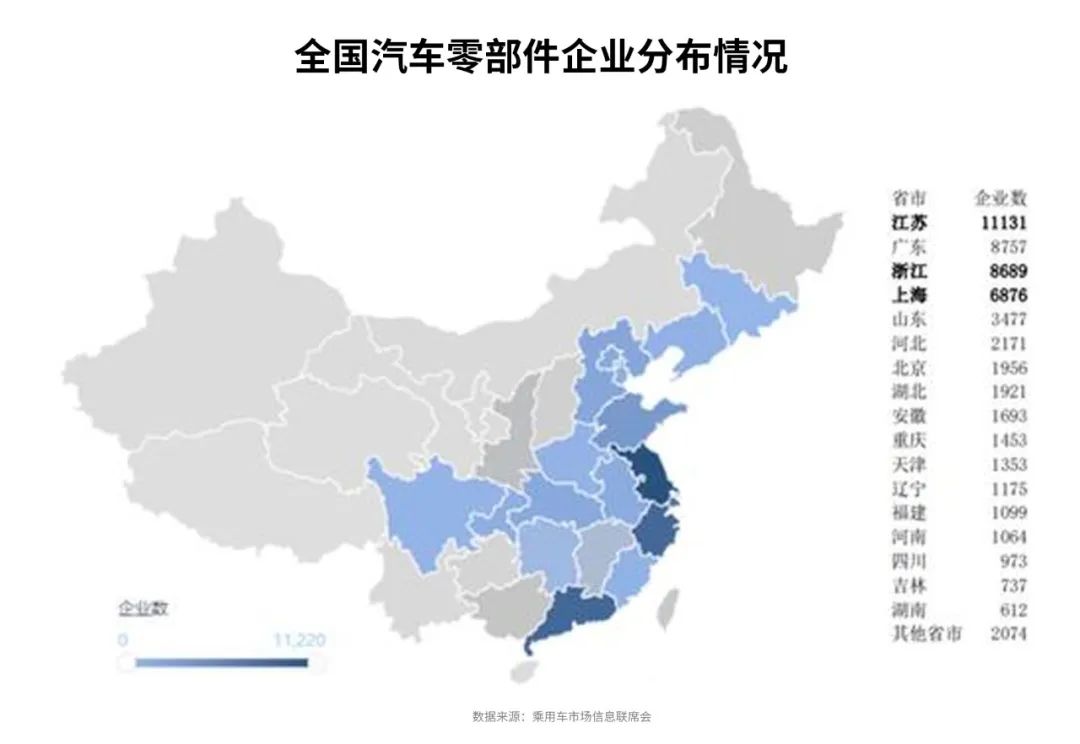

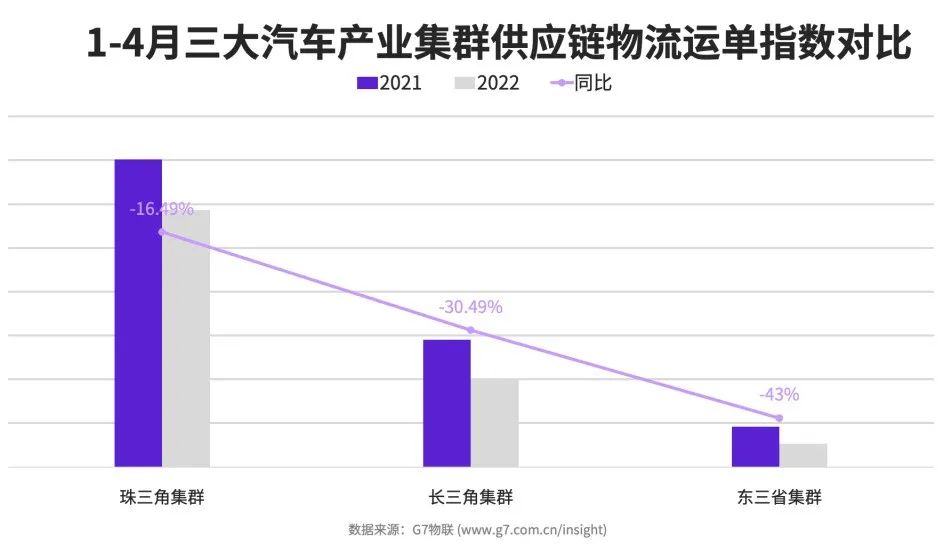

From the G7 IOT big data platform, we can see that the distribution of logistics heat in the national automobile supply chain is relatively regular, in which the main heat is concentrated in the Pearl River Delta, Yangtze River Delta, the three eastern provinces and Beijing Tianjin Hebei. Thanks to the industrial cluster effect and high degree of integration, more than half of the waybills are completed in the region. Take the Yangtze River Delta as an example. In 2021, about 70% of the automobile supply chain logistics flows to the top 10 cities in Shanghai, Jiangsu, Zhejiang and Anhui provinces were concentrated in the Yangtze River Delta.

The reason is that the siphon effect of the industrial chain will occur near some main engine plants with large output, mainly considering factors such as cost, efficiency, storage, transportation and supply cycle. In recent years, China's automobile industry has formed six Automobile Industry Clusters - Yangtze River Delta cluster, Pearl River Delta cluster, Beijing Tianjin Hebei cluster, central triangle cluster, Chengdu Chongqing western cluster and Eastern three provinces cluster. It can be said that they have supported the whole Chinese automobile market. According to the National Bureau of statistics, the national automobile output in 2021 was 26.528 million, of which the top three provinces were Guangdong, Shanghai and Jilin.

The large scale of the automobile industry market, the wide depth of the industrial chain and the deep effect of industrial clusters are the important reasons why the automobile industry bears the brunt of the epidemic. In addition, logistics blocking the supply chain is also the number one problem at present. The AB side of the automobile industry is exposed in the face of the epidemic. The characteristics of clustering and globalization make it impossible for any enterprise in the industrial chain to be alone.

The large scale of the automobile industry market, the wide depth of the industrial chain and the deep effect of industrial clusters are the important reasons why the automobile industry bears the brunt of the epidemic. In addition, logistics blocking the supply chain is also the number one problem at present. The AB side of the automobile industry is exposed in the face of the epidemic. The characteristics of clustering and globalization make it impossible for any enterprise in the industrial chain to be alone.

In the past two months, under the background of the epidemic in Guangdong, Shanghai, Jilin and other places, the closure of cities in various urban areas, the shutdown of enterprises and the rupture of supply chain logistics have brought a fatal blow to the automobile industry. Among them, the importance of Shanghai to the automotive industry is evident. It is not only the headquarters of nearly half of the global auto parts giants and the stationing place of some factories, but also a contributor of one tenth of the national auto output.

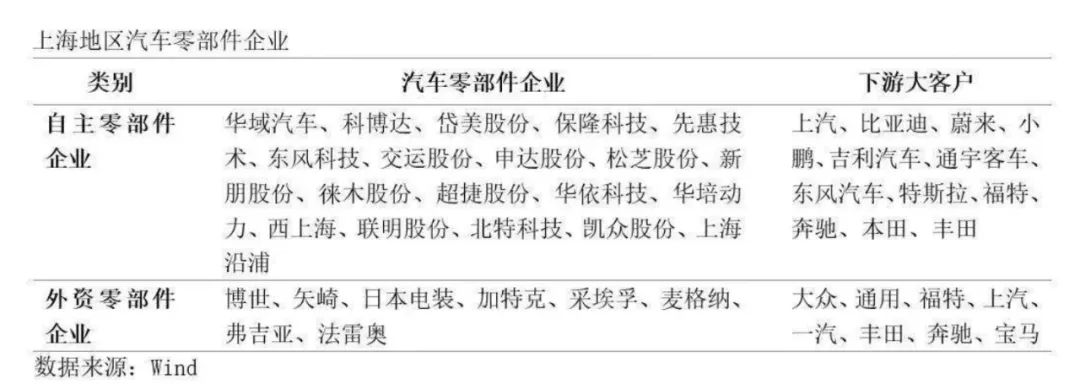

As we all know, due to the large overall sales of SAIC Volkswagen and SAIC GM, the leading position of SAIC Group has always remained stable, making Shanghai automobile industry in the fast lane of development. Since SAIC GM and Volkswagen are German and American, different from the long-term cooperation emphasized by the Japanese, the former is more open and separated between zero and integer relations. Therefore, a large number of parts enterprises have been cultivated to gather around Shanghai. Nine of the top ten parts groups in China are located in Shanghai, namely Bosch, ZF, Magna, Hyundai Mobis, Aisin, Continental, Valeo, Lear and Virginia.

Thanks to the siphon effect of Shanghai automobile industry chain, thousands of large-scale parts enterprises and more than 20000 small and micro enterprises gather in the surrounding Jiangsu and Zhejiang regions, accounting for 44.6% of the total parts enterprises in China, covering almost the whole industry chain of automobiles. If the resumption of work and production is not effectively implemented, it will directly affect SAIC Group, BYD, Weilai automobile, Tesla, Geely, Xiaopeng automobile, Mercedes Benz BMW, including a host of OEMs with huge production capacity around Shanghai.

In addition, the logistics system of the Yangtze River Delta was not able to shut down in time due to the uncontrollable shutdown of the logistics system in January and February 2024, which means that the production efficiency of some logistics platforms in the Yangtze River Delta was not fully reduced due to the uncontrollable shutdown of the logistics system in January and February 2024.

At the same time, the cluster of the three northeastern provinces is also plagued by the epidemic, and the transportation volume of the automobile supply chain decreased by 43% year-on-year. As the cradle of the automobile industry, from the perspective of the whole vehicle, The three northeastern provinces have "FAW Hongqi, FAW Jiefang, FAW Pentium, FAW Volkswagen and other automobile manufacturers; from the perspective of parts, they have the world's top 100 multinational automobile parts enterprises such as mainland China and WeiPai. Behind the blocked logistics of automobile supply chain, many automobile manufacturers are feeling the pain caused by production suspension or limited production capacity. According to the data of the passenger Association, the production of the five main automobile enterprises in Shanghai decreased by 75% month on month compared with March, and the joint venture in Changchun The production of main car enterprises decreased by 54%, and the overall decline in other regions was 38%.

A car has more than 20000 parts. Any supply problem of parts will affect the transmission to the downstream vehicle enterprises, resulting in the inability to produce and ship. Take Weilai automobile as an example. Although its factory is in Hefei, Weilai had to announce a temporary shutdown due to the shortage of upstream parts due to the epidemic in Shanghai.

Public information shows that on April 9, Weilai automobile announced on its official app that it had suspended vehicle production. In this regard, Wei Lai said that since March, due to the epidemic, the company's supply chain partners in Jilin, Shanghai, Jiangsu and other places have stopped production one after another, which has not been restored yet. Due to the above reasons, many users will delay the delivery of their vehicles in the near future. At the same time, due to the continuous sharp rise in global raw material prices since this year, Weilai automobile will adjust the prices of its products from May 10, 2022. The starting prices of es8, ES6 and ec6 models will be increased by 10000 yuan. In terms of baas battery rental price, the rental service fee of long-life battery cell will be adjusted from 1480 yuan / month to 1680 yuan / month.

Coincidentally, on April 13, the tank brand of Great Wall Motors issued a notice on its official app that due to the epidemic, more than 30 cities and counties, including Dandong, Liaoyang, Shenyang, Yingkou and Binzhou, have suspended shipment. At the same time, affected by the epidemic in Shanghai, Jiangsu, Jilin and other places, the production of tank 300 models has been suspended since April 14 due to the suspension and shutdown of 8 supplier partners. Due to the above reasons, the delivery of vehicles of tank 300 users will be delayed.

Coincidentally, on April 13, the tank brand of Great Wall Motors issued a notice on its official app that due to the epidemic, more than 30 cities and counties, including Dandong, Liaoyang, Shenyang, Yingkou and Binzhou, have suspended shipment. At the same time, affected by the epidemic in Shanghai, Jiangsu, Jilin and other places, the production of tank 300 models has been suspended since April 14 due to the suspension and shutdown of 8 supplier partners. Due to the above reasons, the delivery of vehicles of tank 300 users will be delayed.

Tesla, which has a super factory in Shanghai, was affected by the epidemic and stopped production from March 16. Two days later, due to the upgrading of Shanghai control, it suspended the production of its Shanghai factory on March 28. It is reported that the output of Tesla Shanghai plant accounts for more than 50% of the total output in 2021, with a daily output of about 2000-2500 vehicles. According to this calculation, Tesla's current output loss may be about 40000 vehicles.

On March 31, a spokesman for Volkswagen Group said that due to the difficulties in purchasing parts during the epidemic, the Shanghai Anting factory jointly operated by the company and SAIC Group will be partially closed from March 31.

It is reported that SAIC Volkswagen has plant 1, plant 2, plant 3 and new energy vehicle plant in Shanghai, all located in Anting Town, Jiading District, Shanghai.

02

The auto industry began an emergency restart

But logistics is still constrained

In the face of the overall downward trend of the automobile industry, all regions began to restart urgently. On April 16 and April 28, Shanghai successively announced the white list of the first and second batch of enterprises returning to work and production, with a total of 1854, of which automobile manufacturing and parts enterprises account for the most, which is enough to see that the automobile industry has a significant impact on Shanghai's economy.

It is reported that although these enterprises have obtained the permission to resume work, they are facing great difficulties. Employees can focus on closed-loop production. The paralysis of supply chain logistics makes it difficult for raw materials and finished products to enter and leave the factory. The continuous promotion of production and sales has become an important part of constraints. It is easy to resume work and difficult to resume production. According to the survey conducted by Shanghai Securities News on the resumption of production and work of Listed Companies in the Yangtze River Delta region, 72.41% of the 667 listed companies interviewed reported that the epidemic had blocked logistics and broken supply chains.

An employee of a Shanghai auto company said that although the company is trying to promote the production of complete vehicles, the production and assembly of the production line can not be completed on schedule due to the failure of upstream and downstream parts suppliers to supply in time.

An employee of a Shanghai auto company said that although the company is trying to promote the production of complete vehicles, the production and assembly of the production line can not be completed on schedule due to the failure of upstream and downstream parts suppliers to supply in time.

As early as mid and late April, industry analyst Guo Mingxuan said on twitter that compared with the two shift system of the Shanghai factory, Tesla will adopt the one shift system after returning to work this time, so the hourly workload will be directly halved. Based on this calculation, the current parts inventory of the Shanghai factory is only for two and a half weeks, and the subsequent capacity needs to be adjusted according to the situation of the supply chain. In other words, due to the failure of timely supply due to the rupture of supply chain logistics, Tesla's Shanghai plant, which has just resumed work, may face shutdown again.

Similarly, the staff of a car seat company in Jiangsu once told the media: "the factory is still transporting finished products to other places, but the logistics is more complex. Some car enterprise customers have stopped production recently, and our production plans have been forced to be transferred around. Because the suppliers can't supply the goods, we are also facing the problem of shortage of raw materials."

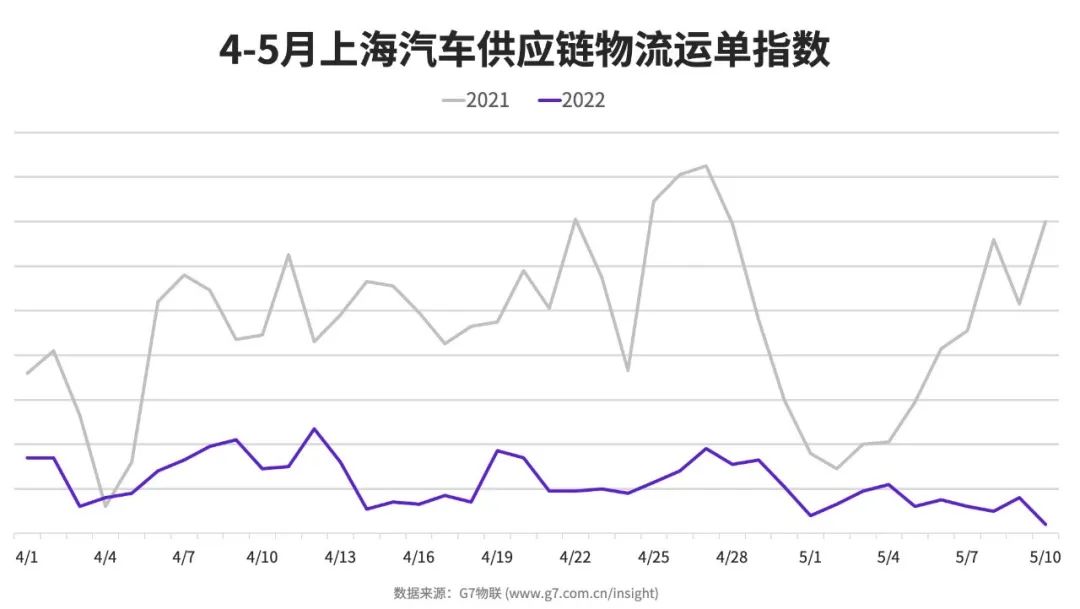

After the outbreak of the epidemic in Shanghai, Jiangsu and other places, the management problems existing in the logistics and transportation link have been increasingly exposed. "Parts can't come in and products can't go out" has become the norm of logistics and transportation at present. According to the G7 IOT big data platform, even if the resumption of work and production began in the middle and late days of Shanghai, the Shanghai automobile supply chain logistics waybill index was still far from that in 2021 year-on-year until May 10, with a year-on-year decline of 73.68% in April 2022.

The resumption of work of enterprises is inseparable from the circulation of goods, especially in the Yangtze River Delta. Due to the deep integration of industrial chains for many years, automobile parts, metal materials and surface treatment raw materials are scattered in various cities in the Yangtze River Delta. It is very important for Shanghai head vehicle manufacturers and parts suppliers to get through the logistics of the whole Yangtze River Delta.

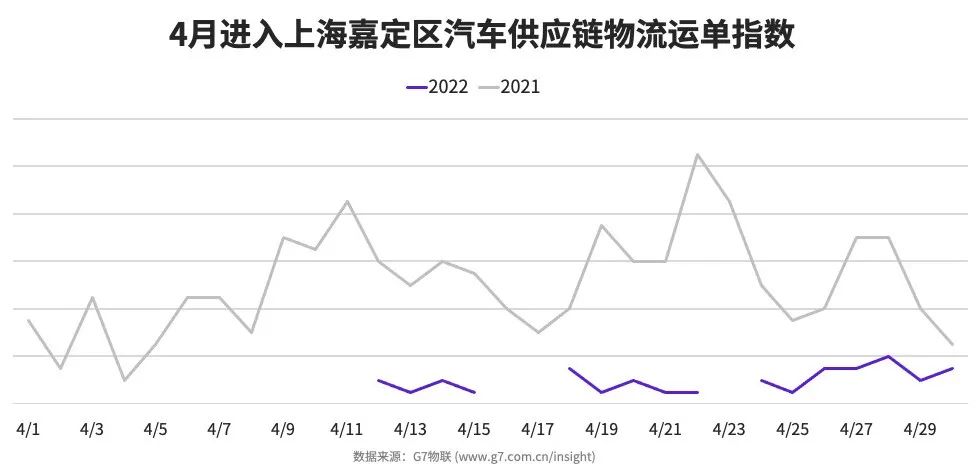

At present, Jiading District is dredging the logistics chain by setting up a transfer station. According to the G7 IOT big data platform, from April 1 to April 12, 2022, the automobile supply chain logistics entering Shanghai Jiading District was almost at a standstill. According to mgk.com, since March 31, the Jiading Anting factory, which lacks raw materials, has entered a shutdown state. Anting town is located at the junction of Shanghai and Jiangsu Province. In front of the layers of epidemic prevention management at the expressway, some truck drivers who lack passes were forced to give up their plans to go to Shanghai and stop in Suzhou.

On April 18, the emergency supply guarantee transfer stations for important materials in the Yangtze River Delta officially began operation. The first batch of 6 transfer stations (4 have been completed), including 2 in Shanghai, which are located in Jiading District and Minhang District respectively, and are constructed and operated by Shanghai Anji suchi logistics. At the same time, we also saw through the G7 Wulian big data platform that on April 18, the automobile supply chain transportation entering Jiading District ushered in the first high point of this month. At present, Jiaxing Anting transfer station has successfully opened two-way transportation channels for auto parts in Shanghai, Hangzhou, Ningbo, Nanjing and other Yangtze River Delta regions, which can meet the transfer demand of 30 vehicles with more than 20 tons per day and ensure the continuous supply of key parts.

On April 18, the emergency supply guarantee transfer stations for important materials in the Yangtze River Delta officially began operation. The first batch of 6 transfer stations (4 have been completed), including 2 in Shanghai, which are located in Jiading District and Minhang District respectively, and are constructed and operated by Shanghai Anji suchi logistics. At the same time, we also saw through the G7 Wulian big data platform that on April 18, the automobile supply chain transportation entering Jiading District ushered in the first high point of this month. At present, Jiaxing Anting transfer station has successfully opened two-way transportation channels for auto parts in Shanghai, Hangzhou, Ningbo, Nanjing and other Yangtze River Delta regions, which can meet the transfer demand of 30 vehicles with more than 20 tons per day and ensure the continuous supply of key parts.

Not long ago, in response to the problem of "poor logistics operation in the Yangtze River Delta", the Ministry of transport stressed that "it is not allowed to add weight at all levels and apply one size fits all". With the gradual improvement of the epidemic situation in Shanghai, it is believed that the impact of supply chain logistics on the resumption of work and production will be gradually reduced.

Under the epidemic, the more heavily dependent industries on the supply chain, the more they can feel the pain caused by the logistics fracture. Even industries with cluster development such as automobiles can only be "close to the horizon" once the logistics circuit breaks. Of course, under the heavy blow, we have also seen the signal that the state and industry actively seek ways and means to dredge logistics. We also believe that after the epidemic subsides, the automobile supply chain logistics will gradually return to the right track. At that time, the automobile industry may reconsider how to coordinate the resources of logistics partners and strengthen the resilience of supply chain logistics behind the cluster development.

Source / G7 IOT (ID: g7_smart)